Engineers who want to test functionality or visualize their designs need prototypes. However, parts ordered from local machine shops often take too long or cost to be a viable part of the design process. That's why modern engineers often turn to rapid prototyping as a quick and efficient manufacturing method.

When to Choose Rapid Prototyping

Engineers use rapid prototyping to manufacture detailed recreations of 3D models. This process is particularly helpful for testing designs, visualizing products, and even comparing different manufacturing materials.

Rapid prototyping is a fast and efficient manufacturing process. Parts that would take days or weeks to create by hand can be machined or printed in a day or less. This means that engineers can order prototypes without adding weeks of wait time to their design process.

Another main benefit of rapid prototyping is the low cost. Most manufacturing methods are only cost-efficient in low batches. However, rapid prototyping methods like 3D printing and CNC machining offer the same price-per-unit regardless of the order size. Engineers can order individual parts on an as-needed basis without worrying about extreme manufacturing costs.

The technologies used for rapid prototyping are extremely detailed and accurate. Rapidly manufactured products look and function just like the original CAD files. With high-quality materials and professional manufacturing, engineers can use rapid prototypes as an accurate presentation of their final design.

In general, rapid prototyping is the right choice for engineers who need:

Quick turnaround times

Single units and small batches

Multiple material choices

Functional prototypes

Detailed visual models

Highly accurate recreations

Customer-ready finishing options

Why to Choose 3D Hubs

3D Hubs is the world's leading provider of on-demand manufacturing services including 3D printing, CNC machining, and injection molding. From small projects to large print runs, 3D Hubs helps engineers and creators turn their designs into a reality.

Any customer can check the viability of a design for production by uploading it to the 3D Hubs online manufacturing platform. Once a CAD file is uploaded, the automatic Design for Manufacturing tool will make sure that the file meets specifications for the chosen manufacturing method. Then, 3D Hubs will generate an instant quote and estimate a lead time for production.

3D Hubs is known for having exceptional short lead times. This comes from 3D Hubs' wide network of global manufacturers. When engineers place an order, the job is sent to the closest available team. This allows quality parts to be delivered less than a week after ordering.

With quick lead times, low prices, and a convenient interface, it's no surprise that so many engineers choose to work with 3D Hubs for rapid prototyping and on-demand manufacturing.

Your Choices: Technologies and Materials

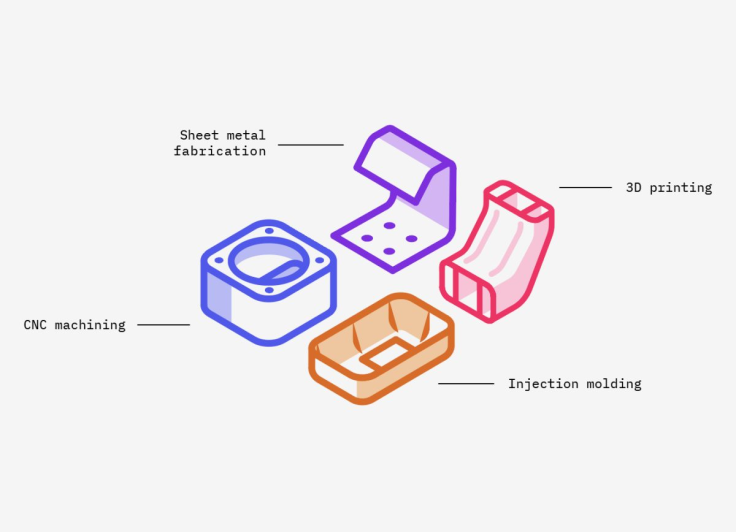

Rapid prototyping is available for both additive and subtractive manufacturing methods. Engineers choose a method based on the preferred material and the shape of the design.

3D printing is one of the most popular choices for rapid prototyping because it can be used to create detailed designs that would not be viable with other manufacturing methods. 3D Hubs' SLS rapid prototyping service is used for highly functional nylon parts with excellent material properties, while the SLA rapid prototyping service is ideal for detailed resin models and cosmetic items. Different printing methods can be used to create thermoplastic or even metal objects.

CNC machining is used to create on-demand metal parts and containers. Machining is a subtractive manufacturing process, so it works better for designs that can be created by removing material from a piece of metal. Metals are available in different strengths and thicknesses to help engineers realize the perfect version of their design.

3D Hubs offers the fastest and most reliable rapid prototyping services on the web. Compare lead times and generate an instant quote when you upload a design to the 3D Hubs online manufacturing platform.