Researchers at Sony and Harvard's Wyss Institute just created an origami-inspired robot. Could this herald the next generation of surgical robots?

In the near future, robots could be playing a crucial part in surgical procedures. Their advantage? Robots have better control and more precise movements than their human counterparts.

However, surgical robots tend to be large and heavy. Often, they take up an entire operating room. And to complicate matters, their tools tend to larger than the tissues in which they operate. The solution: scale it down.

Wyss Institute collaborated with Sony Corporation for this ground-breaking project. The product of their collaboration is a miniature remote manipulator ("mini-RCM"). The mini-RCM is as small as a tennis ball and is as light as a penny.

Mini surgical robots

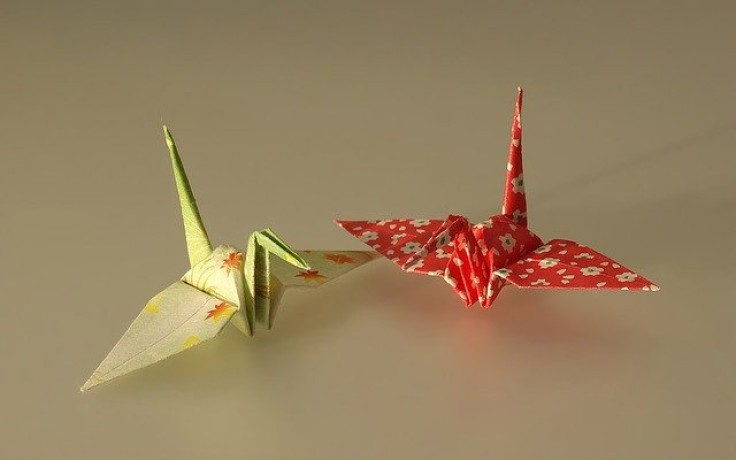

To achieve this feat, the researchers took inspiration from the Japanese art of folding paper. They call the technology "Pop-up MEMS." It is a technique creating miniature machines, developed by the Wyss Institute. This technique makes the process of mass-producing small and complex objects much simpler.

The process involved sandwiching layers of materials. They then laser-cut them to the desired pattern. That pattern creates a three-dimensional shape that allows it to pop-up.

The next step is to create three linear actuators. These mini-LAs will control the movement of the robot. The parallel actuator raises and lowers it while the perpendicular actuator rotates it. On the other hand, the one at the tip extends and retracts the tool.

The team then used a separate technology to build the mini-LAs. They used a special ceramic that changes shape when triggered by electricity. The changed shape then pushes the mini-LAs. It then creates motion, much like a train on tracks. And so it allows the robot to move.

Steadier, more accurate movements

The next step is to put the mini-RCM to the test. They did it by mimicking a teleoperated surgery. The researchers connected the robot to a Phantom Omni device. The device controls the mini-RCM in response to the user's hand movements.

The first test assessed how steady and accurate it is. In the test, the user traced a tiny square using a microscope. That square is no bigger than the ballpoint pens' tip. The user traced the square using his hands and then the mini-RCM. The test revealed that the robot could improve a user's accuracy. To be exact, it reduced the error by as much as 68 percent.

Afterward, they conducted a mock surgical procedure. In the mock surgery, the doctor injected medicine into the eye's tiny veins. They fabricated silicon tubes to serve as the veins. So, the tubes were created to be as small as the tiny veins. The test showed that the robot successfully punctured the target "vein" without damaging nearby veins.

Mini-RCM's other benefits

The mini-RCMs provide other benefits. First, they are easy to set up and install. Second, they can easily be removed from the patient's body in case anything goes wrong.

The teams aim to refine the robot's actuators. They want them to be strong and precise enough for actual operating procedures. The team is also looking into incorporating laser with a shorter impulse. This, in turn, could help improve the robot's sensing resolution.