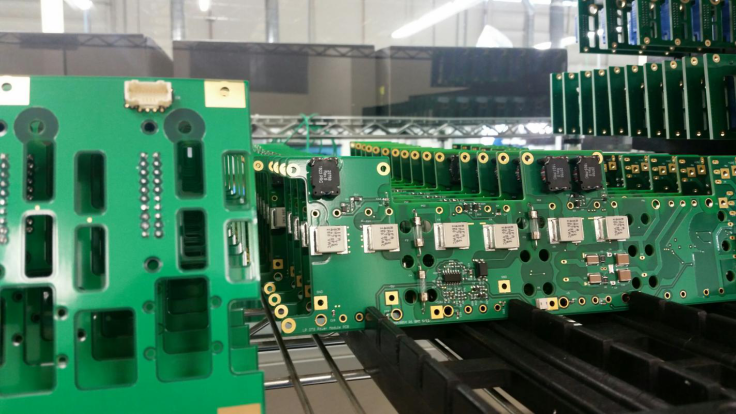

PCB assembly cost cut down is a thinkable subject. PCB is the abbreviated form for printed circuit board assembly that is often used to connect electronic components with their corresponding circuit board connections. Copper is used as wire because of its electrical conductivity and along with this is adjoined a non conductive substrate also. This is the overall set of the circuit assembly.

They can be of a single side board or multilayered board. They can even be double sided as well. However whatever the type may be there is either of two technologies that are used to assemble the PCB assembly with the electronic devices. So it can be "hole" technology. It could even be "surface mount" technology. Hence PCB assembly is of utmost importance in order to boost mechanical support to the electronic devices that they are normally connected with.

PCB assembly cost cut down in most of the cases can be due to cost of manufacturing and assembling which is quite high to bear. On the other hand, if one skips the cost factor, then one might not be assured of getting quality product. So this issue will be taken up here. The best way by which quality as well as cost both could be handled well as the same time, is to find out some interim solution that can mediate and work by satisfying with both these criteria. So instead of being completely focused about the production process, there needs to be some sort of monitoring so as to regulate the cost drop down measures and make it possible. One can start this by outsourcing some parts from the original equipment manufacturers i.e. the OEM's.

There are a few reputed PCA manufacturing companies in China like raypcb. These types of companies are generally involved in manufacturing of circuit boards. However PCB assembly cost cut down is a specialized process and it requires a lot of things put together.

Processes to be monitored on pre manufacturing stage of full manufacturing projects:

All the materials required for developing circuit assemblies should be from original and trusted manufacturing sources.

There should be a careful PCBA testing.

The developers should first make a thorough analysis of the quality of circuit boards before assembling them.

In case of partial manufacturing projects:

This case is a bit less complex from the previous case. Here one can procure the PCB from any source and hand them over for assembling. They can be handled well and executed in order to deliver completely satisfactory result for PCB assembly cost cut down.

Factors affecting cost raise of custom PCB assembly- the ordinary way:

The cost cut down is influenced or affected by a number of factors taken together. Such factors are the assembly type, components place, components package, quantity and overall batch size, certain standards for special parts, the appropriate bill of materials indicating the quantity, specification and other details of the product. It also requires the base board layer count and what materials are we specifically going to need in order to develop this product. This will further increase or decrease the overall cost of the PCB assembly. For example if we decide to use a board that is extremely flexible, then it is obviously better.

However in this case, the cost will one much higher than that it would cost if one would have used a rigid one. This is not everything. Apart from this, one should even be able to consider about what coating is going to be applied, once the development of the PCB assembly is fully over. For this reason, we need to concentrate on what kind of coating is going to be used. There are two options available and one can either use a partial costing or a full coating, whichever is preferable. So coating is further dependent upon the materials, the total number by which coats are applied, the overall level of coverage and the portions are to be entirely or partially left out.

The next factor of consideration for PCB cost cut down to be considered to think over the fact whether full manufacturing can be accompanied with cost cut down, is that of the overall area to be potted and whether the PCB holds compliance or not with lead. There are certain other optimal standards like that of the ITAR or the IPC-A-610 D. However developing a PCB assembly is not everything. One should also check whether it is going to work well or not. How can someone check this? The first and foremost thing that one needs to check is whether the power functions are enabled or not. This can be checked for methods like thermal cycling etc.

Finally, it is also the duty of the developer to be ready with ways to transport this to the user and for this, there should be proper arrangements of shipping facilities available. The delivery of PCB assembly should even be done in such a manner, that it does not get damaged or affected and for this, a part of the overall cost is also to be invested upon the standard bags.

The wiser way for PCB cost cut down is here:

However in case of going for the complete thing in all, if one decides to buy some parts in parts, then it would be wiser enough and the overall cost of PCB assembly can be cut down considerably. Even if you want outsourcing for your business, you need to keep two things in mind. The first is that of the design and engineering section who are responsible for designing the profit. The second is that of the purchase department who sell any product by collecting them from the former source. One very important fact in business is that it should never compromise with the quality of its products for services in order to earn huge profits. This should be the motto of every business. So quality and cost, both can be maintained at the same time, only when one would be able to properly manage these parts at a lower cost by taking consultation from cost curtailing committee, so that one does not have to curtail cost towards buying quality products as well. Hence quality and cost both can be maintained at the same time.