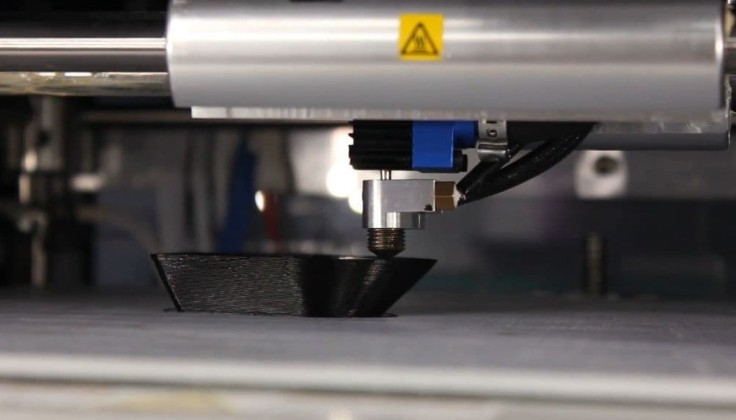

3D printer model Pulsar of renown original equipment manufacturer or OEM company Dyze Design has now been released partially in the market. The company's upcoming most advanced 3D printers are now open for public as preorder.

The newest pellet printer extruder offering by Dyze Design features a high flow rate, where it is made from plastic. Its aim is to produce high quality 3D print parts that measure at least 1 cubic meter or more in a fast, efficient, and proper manner.

ALSO READ: 'New Normal' for the Entertainment Industry Emerges | Shows Slowly Resume On-Site Shoots

According to Dyze Design's Chief Marketing Officer (CMO) Simon Duchaine, the technology Pulsar offers which is the pellet-based extrusion could be classified and labeled as a real "game-changer" in today's 3D printing industry. He implied that it not just produces more precise and higher quality of output, but it could save up resources as it would reduce materials costs "by up to 10 times", and could open up possibilities of using newer polymer types to be sued for production of 3D parts.

He also described pellet-based systems or extrusion systems as "in-demand", as it flows smoothly on the current trends of the 3D modeling and printing industry. Companies and other establishments that deal with on hand product creation seeks the use of technologies that caters what pellet-based systems or extrusion systems offer in the enterprise and business market.

Pulsar's Features and Specs

Pulsar's features three parts dedicated for the polymer section of the machine. It includes the anti-oozing mechanism which helps to lessen heat by providing a fine and even flow of produced by its nozzle heater on the bottom part. The middle part is dedicated for providing stability on the polymer while being on a temperature designated as long as it does not affect it, like overheating or being under the right temperature. And the top part, which is designed to utilize heat to melt the polymer while it receives the cold pellets.

It also has a screw design customized for its 3D printing capability to be more highlighted with top resolution quality as the final output. Its overall structure lists 48 cm by 17 cm by 13 cm as its dimensions.

The latest 3D printer from Dyze Design is made with the function of integrating pellets or known as granules. Those have a measure of approximately 3mm to 5mm in size which could be originated from some materials that are polymer-based engineering materials that are far more advanced, like the High Impact Polystyrene or HIPS, the Polytheretherketone or the Polyvinyl Alcohol or the PVA.

Its high capacity in terms of its maximum operating temperature that could go as high as 500 degrees is also considered a top mark for the model, along with its integrated liquid-cooling loop system. It would be also easy for different standard open-source firmware in the market to maximize Pulsar.

Dyze Design is based on Montreal, Quebec, Canada and was known for developing high-performance technology for the 3D printing industry since it was established in 2015. Their older 3D printer models include the DyzeXtruder GT and DyzeXtruder Pro, and the Typhoon high-flow extruder.

ALSO READ: Tesla CEO Elon Musk Gives a Glimpse of Future Offerings; Hatchbacks, 621-mile Cars Possible